The Process of Creating Biofuel from Waste

In a world increasingly focused on sustainability, the transformation of waste materials into biofuel stands out as a beacon of hope. Imagine taking what we typically throw away—food scraps, agricultural leftovers, and even municipal waste—and turning it into a valuable energy source. This process not only helps reduce landfill waste but also significantly lowers our reliance on fossil fuels, paving the way for a greener future. So, how does this magical transformation occur? Let’s dive into the steps involved in creating biofuel from waste and uncover the myriad benefits, technologies, and challenges that come with it.

Biofuels are essentially renewable energy sources derived from organic materials, and they come in various forms. The most common types include biodiesel and bioethanol, each produced through different methods. The production process often involves converting biomass—organic material from plants and animals—into fuel that can power vehicles and generate electricity. By utilizing biofuels, we can significantly reduce greenhouse gas emissions and mitigate the effects of climate change. This is crucial, as traditional fossil fuels release large amounts of carbon dioxide when burned, contributing to global warming. In contrast, biofuels can be produced sustainably, making them a vital part of our energy landscape.

When it comes to biofuel production, the sources of waste are plentiful and diverse. From agricultural residues to food waste and municipal solid waste, each source has its unique potential for conversion into biofuel. Agricultural residues like straw and husks are often left to decompose, but they can be a goldmine for biofuel production. Food waste, which constitutes a significant portion of our daily trash, can also be converted into energy, reducing the burden on landfills. Even municipal solid waste, which encompasses everything from packaging materials to old furniture, can be processed to extract valuable energy resources.

Agricultural residues are a prime candidate for biofuel production. These materials, which include leftover straw, corn stalks, and husks, are often abundant and underutilized. Not only do they provide a sustainable energy source, but their use also helps reduce environmental impact by minimizing waste. When processed correctly, these residues can be transformed into biofuels through various methods, contributing to a circular economy where waste is repurposed into energy.

Several processing techniques are employed to convert agricultural residues into biofuels. Among the most effective are fermentation and anaerobic digestion. Fermentation involves the breakdown of sugars in the biomass by microorganisms to produce ethanol, while anaerobic digestion uses bacteria to decompose organic material in the absence of oxygen, resulting in biogas. Both methods have proven effective, but their efficiency can vary depending on the type of biomass used and the specific conditions of the process.

Despite their potential, agricultural residues face several challenges in biofuel production. Issues such as collection, transportation, and processing costs can hinder their widespread use. For instance, gathering these materials from vast agricultural fields can be labor-intensive and costly. Additionally, transporting bulky residues to processing facilities adds another layer of expense. Overcoming these challenges is crucial for maximizing the potential of agricultural residues in the biofuel sector.

Food waste is often overlooked as a valuable source of biofuel. With millions of tons of food ending up in landfills each year, innovative methods for converting food scraps into bioenergy are gaining traction. Techniques like anaerobic digestion and composting not only help reduce landfill waste but also produce biogas that can be used for heating or electricity generation. By focusing on food waste conversion, we can tackle two pressing issues—waste management and energy production—simultaneously.

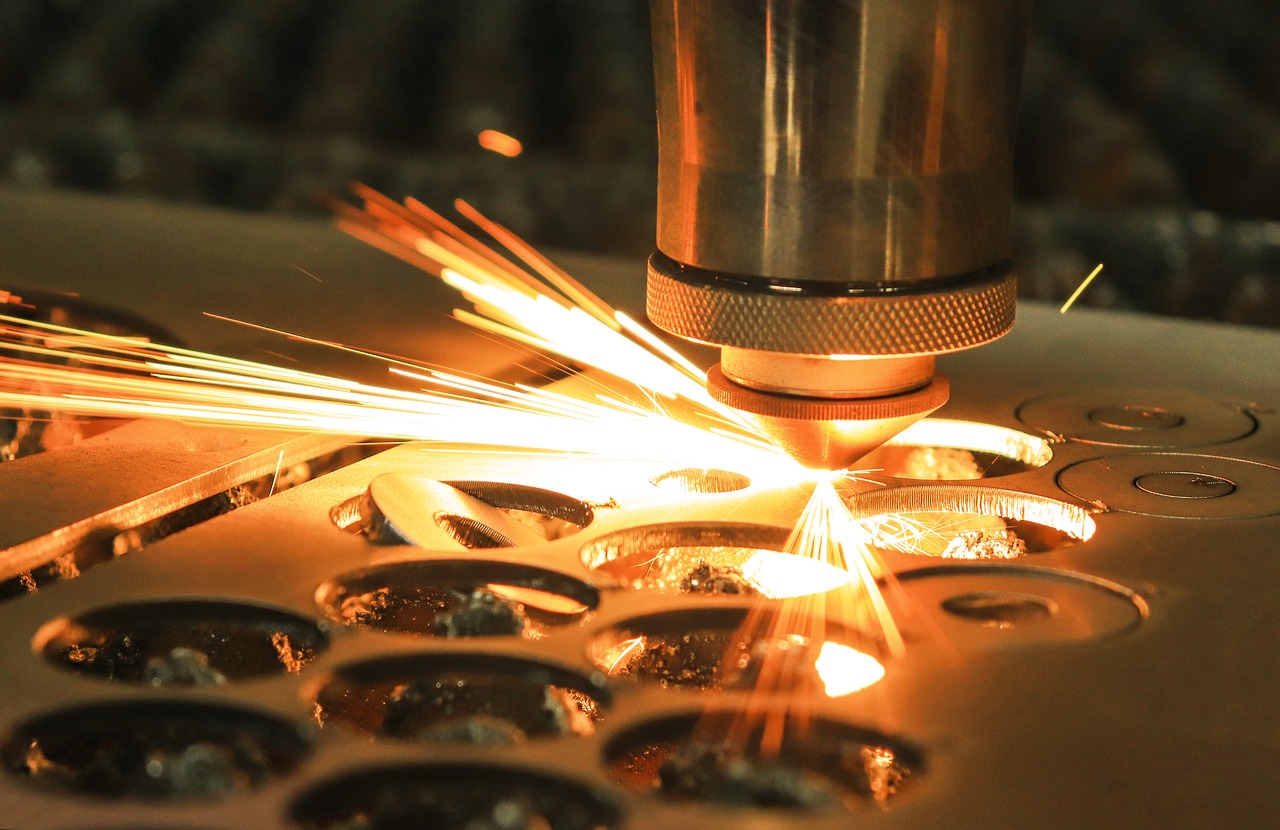

The journey from waste to biofuel is facilitated by several cutting-edge technologies. These include enzymatic hydrolysis and gasification, both of which play a significant role in enhancing the efficiency of biofuel production. Enzymatic hydrolysis involves using enzymes to break down complex organic materials into simpler sugars, which can then be fermented into biofuels. On the other hand, gasification converts organic materials into syngas, a mixture of hydrogen and carbon monoxide that can be further processed into various fuels.

Enzymatic hydrolysis is a promising technique for breaking down complex organic materials. By utilizing specific enzymes, this process effectively transforms biomass into fermentable sugars, making it easier to produce biofuels. The advantages of enzymatic hydrolysis include higher efficiency and lower energy requirements compared to traditional methods, making it an attractive option for biofuel producers.

The gasification process is another innovative method that transforms organic materials into syngas. This syngas can be used as a precursor for biofuels, providing a flexible and efficient way to harness energy from waste. The benefits of gasification include its ability to handle a wide variety of feedstocks and its potential to produce clean energy with lower emissions, reinforcing its role in sustainable energy production.

The environmental advantages of biofuels are significant. By utilizing waste materials, biofuel production contributes to reduced carbon emissions and provides effective waste management solutions. This process not only helps in combating climate change but also promotes sustainability by closing the loop on waste. By turning trash into treasure, we can create a cleaner, greener planet for future generations.

The economic implications of biofuel production are substantial. The industry has the potential to create numerous jobs, from collection and processing to distribution and sales. Additionally, investing in waste-to-biofuel initiatives can foster energy independence, reducing reliance on imported fossil fuels. As more companies and governments recognize the value of biofuels, we can expect to see a surge in investment opportunities within this burgeoning sector.

The future of biofuels from waste looks promising, thanks to ongoing technological advancements and a growing awareness of environmental issues. As researchers continue to innovate and improve biofuel production methods, we can anticipate a shift towards more sustainable practices. Trends such as increased investment in biofuel technology and a focus on reducing waste will drive the industry forward, making biofuels an integral part of our energy landscape.

- What types of waste can be converted into biofuel? Various types of waste, including agricultural residues, food waste, and municipal solid waste, can be converted into biofuel.

- How does the process of fermentation work? Fermentation involves breaking down sugars in biomass using microorganisms to produce ethanol.

- What are the environmental benefits of biofuels? Biofuels help reduce greenhouse gas emissions and provide effective waste management solutions.

- Can biofuels contribute to energy independence? Yes, biofuels can reduce reliance on imported fossil fuels and promote energy independence.

Understanding Biofuels

Biofuels are an innovative solution in the quest for sustainable energy, derived from organic materials, and they play a vital role in reducing our dependency on fossil fuels. Essentially, biofuels can be categorized into two main types: first-generation and second-generation biofuels. First-generation biofuels are produced from food crops like corn and sugarcane, while second-generation biofuels are made from non-food biomass, such as agricultural residues and waste materials.

The production methods for biofuels vary widely, but they typically involve processes like fermentation, transesterification, and gasification. For instance, fermentation is commonly used for producing ethanol from sugar-rich plants, while transesterification is the process used to convert oils into biodiesel. These methods not only provide an alternative energy source but also help in mitigating greenhouse gas emissions, making them a crucial player in the fight against climate change.

One of the key advantages of biofuels is their ability to significantly reduce carbon emissions compared to traditional fossil fuels. According to research, biofuels can lower greenhouse gas emissions by up to 80% when compared to gasoline. This reduction is largely due to the fact that the carbon dioxide released during the combustion of biofuels is offset by the carbon dioxide absorbed by the plants during their growth. However, the journey of biofuels is not without its challenges, including land use competition and the need for sustainable sourcing practices.

To further understand the impact of biofuels, let’s take a look at some of the key benefits:

- Renewable Source: Biofuels are derived from renewable resources, which means they can be replenished over time.

- Waste Reduction: Converting waste into biofuels helps reduce the amount of waste sent to landfills.

- Energy Security: By producing biofuels locally, countries can reduce their dependence on imported fossil fuels.

In conclusion, biofuels represent a promising alternative to fossil fuels, contributing to energy sustainability and environmental protection. As technology advances and awareness grows, the potential for biofuels to reshape our energy landscape becomes increasingly tangible.

Sources of Waste for Biofuel

When we think about biofuel production, one of the most exciting aspects is the variety of waste materials that can be transformed into energy. This not only helps in managing waste but also contributes to a more sustainable future. So, what are the common sources of waste that can be converted into biofuels? Let's dive into it!

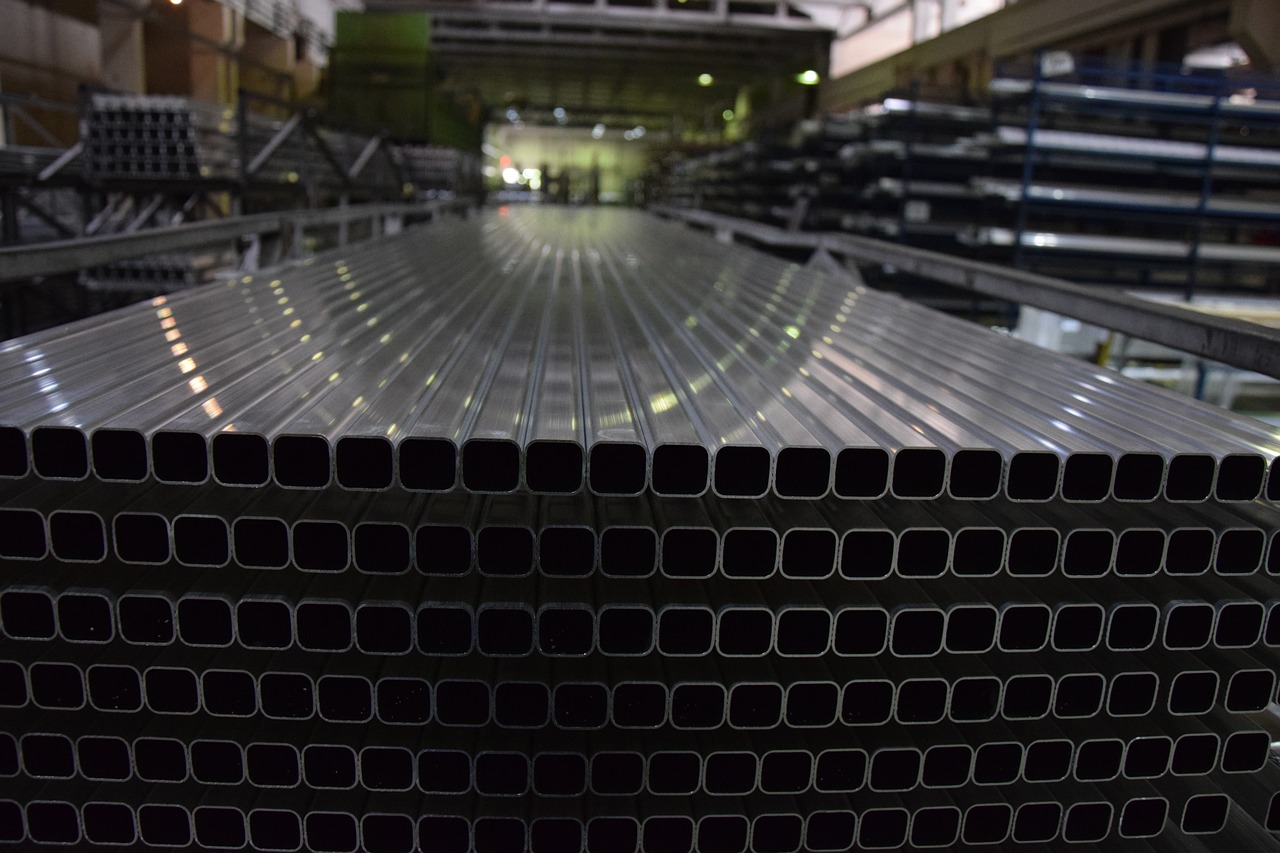

First off, we have agricultural residues. These include leftover materials from farming activities, such as straw, husks, and corn stalks. Surprisingly, a significant amount of these residues often ends up being burned or left to decompose, releasing carbon into the atmosphere. However, with the right processing techniques, they can be converted into valuable biofuels. Imagine turning what was once considered trash into a renewable energy source! It's like finding gold in your backyard.

Next on the list is food waste, which is a massive contributor to landfills. In fact, about one-third of all food produced globally is wasted, which translates to approximately 1.3 billion tons every year. This waste not only takes up space in landfills but also generates methane, a potent greenhouse gas. Fortunately, innovative methods have emerged to convert food scraps into bioenergy. By doing so, we can significantly reduce landfill waste while generating energy that can power our homes and businesses. It’s a win-win situation!

Moreover, we cannot overlook municipal solid waste. This category encompasses everything from discarded packaging to old furniture. As urban populations grow, the amount of municipal solid waste increases, leading to a pressing need for effective waste management solutions. By employing advanced technologies, we can convert this waste into biofuels, thereby decreasing the burden on landfills and providing a renewable energy source. It’s as if we’re turning our trash into treasure!

In summary, the sources of waste for biofuel production are diverse and abundant. From agricultural residues to food waste and municipal solid waste, each category presents unique opportunities for conversion into renewable energy. The challenge lies in efficiently processing these materials, but the potential benefits for our environment and energy independence are enormous. So next time you throw something away, remember: it could be part of the solution to our energy crisis!

- What types of waste can be converted into biofuels? Agricultural residues, food waste, and municipal solid waste are common sources.

- How does converting waste into biofuel help the environment? It reduces landfill waste, lowers greenhouse gas emissions, and promotes renewable energy.

- Are there any technologies used in biofuel production? Yes, techniques like fermentation, anaerobic digestion, enzymatic hydrolysis, and gasification are commonly used.

Agricultural Residues

Agricultural residues, often overlooked, are a treasure trove of potential when it comes to biofuel production. These materials, which include everything from straw and husks to corn stalks and sugarcane bagasse, are abundant byproducts of farming activities. Instead of letting them decompose in the fields or, worse, burning them and contributing to air pollution, we can transform these residues into a sustainable energy source. Imagine turning what was once considered waste into something valuable—it's like finding gold in your backyard!

The processing of agricultural residues into biofuels not only helps in waste management but also plays a significant role in reducing greenhouse gas emissions. When these residues are left to rot, they release methane, a potent greenhouse gas. By converting them into biofuels, we can significantly cut down on these emissions. It's a win-win situation: farmers can earn extra income from what was previously seen as waste, and we can help combat climate change. Isn't it fascinating how something so simple can have such a profound impact?

However, the journey from agricultural residue to biofuel isn't without its hurdles. Let's take a closer look at some of the main processing techniques used to convert these materials into usable energy:

| Processing Technique | Description | Advantages |

|---|---|---|

| Fermentation | A biological process that converts sugars into ethanol using microorganisms. | High efficiency in converting biomass to fuel; can utilize a variety of feedstocks. |

| Anaerobic Digestion | A process where microorganisms break down organic materials in the absence of oxygen to produce biogas. | Produces renewable energy and organic fertilizers; reduces waste volume. |

| Pyrolysis | Thermal decomposition of organic material at elevated temperatures in the absence of oxygen. | Can convert a wide range of feedstocks; produces bio-oil, biochar, and syngas. |

Each of these methods has its own unique benefits and challenges, making it essential to choose the right one based on the type of agricultural residue being processed. For instance, fermentation is particularly effective for sugar-rich materials, while anaerobic digestion works wonders with wet organic waste. The choice of method can greatly influence the efficiency and cost-effectiveness of biofuel production.

Despite the clear benefits, there are significant challenges in utilizing agricultural residues for biofuel production. Issues like collection logistics, transportation costs, and the need for proper processing facilities can hinder widespread adoption. Farmers may find it difficult to gather and transport these residues economically, especially when competing with other uses for their land and resources. It’s like trying to find a needle in a haystack; the potential is there, but the obstacles can be daunting.

In conclusion, agricultural residues represent a promising avenue for biofuel production, but unlocking their potential requires overcoming various challenges. With the right technologies and strategies in place, we can harness these materials to create a cleaner, more sustainable energy future.

- What are agricultural residues? Agricultural residues are byproducts of farming activities, such as straw, husks, and stalks, that can be used to produce biofuels.

- How can agricultural residues be converted into biofuels? They can be processed using techniques like fermentation, anaerobic digestion, and pyrolysis.

- What are the environmental benefits of using agricultural residues for biofuel? Utilizing these residues helps reduce greenhouse gas emissions, manage waste more effectively, and promote sustainable energy production.

- What challenges exist in the utilization of agricultural residues? Key challenges include collection logistics, transportation costs, and the need for appropriate processing facilities.

Processing Techniques

When it comes to transforming agricultural residues into biofuels, the choice of processing techniques is crucial. These methods not only determine the efficiency of biofuel production but also influence the overall sustainability of the process. Among the most widely used techniques are fermentation and anaerobic digestion, each with its unique advantages and applications.

Fermentation is a biological process that converts sugars into alcohol or acids using microorganisms, primarily yeast. This technique is particularly effective for converting starch-rich materials, such as corn and wheat, into ethanol. The process involves several steps, including pretreatment, hydrolysis, and fermentation. During pretreatment, the lignocellulosic biomass is broken down to make the sugars more accessible. This can be achieved through physical, chemical, or biological methods, each with varying degrees of effectiveness and environmental impact.

On the other hand, anaerobic digestion is a process that breaks down organic matter in the absence of oxygen, resulting in the production of biogas, which primarily consists of methane and carbon dioxide. This technique is particularly suited for wet waste materials, such as food scraps and manure. The anaerobic digestion process involves four key stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Each stage plays a critical role in breaking down complex organic materials into simpler compounds, ultimately producing valuable biogas that can be used for heating, electricity generation, or as a vehicle fuel.

Both techniques have their pros and cons. For instance, fermentation is known for producing high yields of ethanol, but it often requires significant energy input for the pretreatment phase. Conversely, anaerobic digestion is more energy-efficient and can handle a wider variety of organic materials, but the quality of biogas can vary based on the feedstock used.

To illustrate the differences between these processing techniques, here's a simple comparison table:

| Processing Technique | Feedstock Type | End Product | Energy Efficiency |

|---|---|---|---|

| Fermentation | Starch-rich materials | Ethanol | Moderate |

| Anaerobic Digestion | Wet organic waste | Biogas (Methane) | High |

In conclusion, the choice of processing technique significantly impacts the overall success of biofuel production from agricultural residues. As we continue to innovate and improve these methods, we can unlock the full potential of waste materials, paving the way for a sustainable energy future.

- What are the main benefits of using fermentation for biofuel production? Fermentation allows for high yields of ethanol from starch-rich feedstocks, making it a popular choice in the biofuel industry.

- How does anaerobic digestion contribute to waste management? Anaerobic digestion effectively reduces the volume of organic waste, producing biogas that can be used as a renewable energy source.

- Can both techniques be used simultaneously? Yes, some facilities use a combination of fermentation and anaerobic digestion to maximize biofuel production from a variety of feedstocks.

Challenges in Utilization

While the potential for biofuel production from agricultural residues is immense, several challenges hinder its widespread utilization. First and foremost, the collection of these residues can be quite complex. Farmers may not have the necessary infrastructure to gather and store materials like straw, husks, and other organic waste efficiently. This lack of infrastructure leads to significant amounts of valuable biomass being left unused in the fields, which is not only a waste of resources but also a missed opportunity for sustainable energy production.

Another challenge lies in the transportation of agricultural residues. Many farms are located in remote areas, making it costly and logistically difficult to transport these materials to processing facilities. The expenses associated with transport can significantly impact the overall economics of biofuel production. When you consider the costs of labor, fuel, and vehicle maintenance, it quickly becomes clear that transporting agricultural waste is not as straightforward as it may seem.

Moreover, the processing costs involved in converting agricultural residues into biofuels can be prohibitive. The technologies required for efficient conversion, such as fermentation and anaerobic digestion, often involve high initial investments and operational costs. For smaller farms or startups, these expenses can be a significant barrier to entry, preventing them from participating in the biofuel market. In many cases, the financial return on investment may not justify the costs involved, leading to hesitation in adopting these technologies.

Lastly, there is the issue of regulatory hurdles. In many regions, the biofuel industry is still evolving, and existing regulations may not adequately support the innovative practices needed for biofuel production from agricultural residues. Compliance with environmental standards and safety regulations can create additional layers of complexity, discouraging potential investors and producers from entering the market.

In summary, while the utilization of agricultural residues for biofuel production presents a promising opportunity for sustainable energy, it is essential to address these challenges. By improving infrastructure, reducing transportation costs, making processing more economical, and streamlining regulations, we can unlock the full potential of biofuels derived from waste materials.

- What are biofuels? Biofuels are renewable energy sources made from organic materials, which can replace fossil fuels and help reduce greenhouse gas emissions.

- What types of waste can be converted into biofuels? Common sources include agricultural residues, food waste, and municipal solid waste.

- What are the main challenges in producing biofuels from waste? Key challenges include collection and transportation of waste, processing costs, and regulatory hurdles.

- How does enzymatic hydrolysis work? Enzymatic hydrolysis involves using enzymes to break down complex organic materials into simpler sugars, which can then be fermented into biofuels.

- What is gasification? Gasification is a process that converts organic materials into syngas, which can be further processed into various types of biofuels.

Food Waste Conversion

Food waste is often seen as a burden, piling up in landfills and contributing to greenhouse gas emissions. However, this seemingly useless waste has the potential to be transformed into a valuable energy resource through innovative conversion processes. By utilizing food scraps, we can not only reduce the amount of waste that ends up in landfills but also produce biofuels that can power our vehicles and homes. It's a win-win situation!

The conversion of food waste into biofuel typically involves several fascinating methods. One of the most common techniques is anaerobic digestion, where microorganisms break down organic matter in the absence of oxygen. This process results in the production of biogas, primarily composed of methane, which can be used as a clean energy source. The remaining material, known as digestate, can be utilized as a nutrient-rich fertilizer, thus completing the cycle of sustainability.

Another innovative approach is the use of enzymatic hydrolysis, where enzymes are employed to break down complex carbohydrates in food waste into simpler sugars. These sugars can then be fermented by yeast to produce ethanol, a type of biofuel. This method not only enhances the efficiency of the conversion process but also maximizes the energy yield from food scraps.

Here’s a quick overview of the two main methods for converting food waste:

| Method | Description | End Product |

|---|---|---|

| Anaerobic Digestion | Microorganisms break down organic matter without oxygen. | Biogas (methane) and digestate (fertilizer) |

| Enzymatic Hydrolysis | Enzymes convert complex carbohydrates into simple sugars. | Ethanol (biofuel) |

Despite the promising potential of food waste conversion, there are challenges to overcome. The logistics of collecting and processing food waste can be complex, requiring a well-coordinated system to ensure efficiency. Moreover, public awareness and participation are crucial in reducing food waste at the source, which ultimately enhances the availability of feedstock for biofuel production.

In conclusion, converting food waste into biofuel is not just a technological challenge but also a societal opportunity. By embracing this sustainable practice, we can significantly reduce our environmental footprint while simultaneously creating a renewable energy source. The future of food waste conversion is bright, and with continued innovation and community involvement, we can harness the potential of our food scraps for a cleaner, greener world.

- What types of food waste can be converted into biofuel? Almost any organic food waste can be used, including fruits, vegetables, and even leftover meals.

- How does anaerobic digestion work? It involves microorganisms breaking down organic materials in a controlled, oxygen-free environment to produce biogas.

- Is the process of converting food waste into biofuel expensive? While there are initial costs, the long-term benefits and savings on waste disposal can outweigh them.

- Can I participate in food waste conversion? Yes! Many communities offer programs for composting and food waste collection that contribute to biofuel production.

Technologies for Biofuel Production

When it comes to producing biofuels from waste, technology plays a pivotal role in ensuring efficiency and sustainability. Various methods have been developed to convert organic waste into usable energy, each with its unique processes and advantages. Understanding these technologies not only highlights their effectiveness but also sheds light on the future of renewable energy. Among the most notable techniques are enzymatic hydrolysis and gasification, both of which have transformed the landscape of biofuel production.

Enzymatic hydrolysis is a fascinating process that employs enzymes to break down complex carbohydrates found in organic materials. Imagine trying to untangle a knotted necklace; enzymes act like skilled hands, gently loosening the knots to free the strands. This method is particularly effective for converting lignocellulosic biomass, such as agricultural residues, into fermentable sugars, which can then be fermented into ethanol. The beauty of enzymatic hydrolysis lies in its specificity—enzymes can be tailored to target specific components of the biomass, making the process not only efficient but also highly adaptable.

Another groundbreaking technology is gasification, which transforms organic materials into a synthetic gas, or syngas. This process involves heating the biomass in a low-oxygen environment, which breaks down the material into simpler molecules. Think of it as a controlled burn that captures the smoke rather than letting it escape. The syngas produced can be further processed to create various biofuels, including diesel and methanol. Gasification is particularly advantageous because it can handle a wide range of feedstocks, including municipal solid waste, making it a versatile option for biofuel production.

Both enzymatic hydrolysis and gasification have their own sets of benefits and challenges. For instance, enzymatic hydrolysis is generally more efficient for specific biomass types but can be costly due to enzyme production and processing time. On the other hand, gasification offers a broader application but may require more complex infrastructure and technology to manage the syngas produced. The table below summarizes these technologies, highlighting their key features:

| Technology | Process | Advantages | Challenges |

|---|---|---|---|

| Enzymatic Hydrolysis | Breaks down biomass using specific enzymes | High efficiency and specificity | Costly enzyme production |

| Gasification | Converts biomass into syngas through low-oxygen heating | Versatile feedstock options | Complex infrastructure requirements |

As we delve deeper into these technologies, it becomes clear that they not only contribute to biofuel production but also play a significant role in addressing global energy challenges. By harnessing waste materials and transforming them into valuable energy sources, we pave the way for a more sustainable future. Moreover, advancements in these technologies continue to emerge, promising even greater efficiency and lower costs in the years to come.

What are biofuels?

Biofuels are renewable energy sources derived from organic materials, such as plants and waste products. They can be used as alternatives to fossil fuels.

How are biofuels produced?

Biofuels can be produced through various methods, including fermentation, enzymatic hydrolysis, and gasification, depending on the type of feedstock used.

What types of waste can be converted into biofuels?

Common waste sources include agricultural residues, food waste, and municipal solid waste, all of which can be processed to create biofuels.

What are the environmental benefits of biofuels?

Biofuels can significantly reduce greenhouse gas emissions, promote waste management solutions, and contribute to energy independence.

Are there any challenges in biofuel production?

Yes, challenges include collection and transportation costs, processing efficiency, and the need for advanced technologies to optimize production.

Enzymatic Hydrolysis

Enzymatic hydrolysis is a cutting-edge technique that plays a pivotal role in the conversion of complex organic materials into biofuels. At its core, this process involves the use of enzymes to break down polysaccharides—large carbohydrate molecules—into simpler sugars. This transformation is crucial because sugars serve as the primary feedstock for fermentation, ultimately leading to the production of biofuels like ethanol. Imagine trying to unlock a treasure chest; enzymes act as the keys that open up the complex structures found in waste materials, making the valuable sugars readily available for further processing.

The beauty of enzymatic hydrolysis lies in its efficiency and specificity. Unlike traditional methods that may require harsh chemicals or extreme conditions, enzymatic processes operate under milder conditions, which not only preserves the integrity of the organic materials but also reduces the energy input required. This gentle approach minimizes the formation of unwanted byproducts, enhancing the overall yield of biofuels. In fact, studies have shown that enzymatic hydrolysis can achieve conversion rates of up to 90%, making it a highly effective method in the biofuel production landscape.

However, the success of enzymatic hydrolysis is heavily dependent on several factors, including:

- Enzyme Selection: The choice of enzymes is critical. Different enzymes target specific bonds in polysaccharides, so selecting the right combination can significantly enhance the hydrolysis process.

- Substrate Characteristics: The type of organic material being processed—be it agricultural residues, food waste, or municipal solid waste—can influence the efficiency of hydrolysis. For instance, lignocellulosic materials, which are rich in cellulose, require different treatment compared to starch-based substrates.

- Reaction Conditions: Factors such as temperature, pH, and reaction time must be optimized to create an environment conducive to enzyme activity.

Despite its advantages, enzymatic hydrolysis does face challenges. The cost of enzyme production can be high, and ensuring the stability of enzymes during the hydrolysis process is crucial for maintaining efficiency. Ongoing research is focused on developing more cost-effective enzyme production methods and improving enzyme stability, which could further enhance the viability of this technique in large-scale biofuel production.

In conclusion, enzymatic hydrolysis stands out as a promising method for converting waste into biofuels. By leveraging the power of enzymes to unlock sugars from complex organic materials, this process not only contributes to sustainable energy production but also helps in managing waste effectively. As technology advances and research continues, we can expect enzymatic hydrolysis to play an even more significant role in the future of biofuels.

What is enzymatic hydrolysis?

Enzymatic hydrolysis is a process that uses enzymes to break down complex carbohydrates into simpler sugars, which can then be fermented to produce biofuels.

What are the advantages of using enzymatic hydrolysis for biofuel production?

This method is efficient, operates under mild conditions, and minimizes unwanted byproducts, leading to higher yields of biofuels.

What types of materials can be processed using enzymatic hydrolysis?

A variety of organic materials, including agricultural residues, food waste, and other biomass, can be effectively processed using this technique.

Are there any challenges associated with enzymatic hydrolysis?

Yes, challenges include the high cost of enzyme production and the need for optimized reaction conditions to ensure efficiency.

Gasification Process

The is a transformative technique that converts organic materials, such as agricultural waste, into a valuable gas known as syngas (synthetic gas). This process involves heating the organic material in a low-oxygen environment, which breaks down the material into its fundamental components. Imagine the way a campfire crackles and pops as it consumes wood; gasification works in a similar fashion but with a controlled environment that optimizes efficiency and minimizes emissions.

During gasification, the organic feedstock undergoes several stages: drying, pyrolysis, combustion, and reduction. Each of these stages plays a crucial role in ensuring that the maximum amount of energy is extracted from the waste material. Here’s a brief breakdown of these stages:

- Drying: The moisture content of the organic material is reduced to enhance the efficiency of the gasification process.

- Pyrolysis: The material is heated in the absence of oxygen, causing it to decompose into volatile gases, bio-oil, and char.

- Combustion: A small amount of oxygen is introduced to burn some of the char, generating heat that drives the process further.

- Reduction: The remaining solid char reacts with the gas to produce syngas, primarily composed of hydrogen and carbon monoxide.

One of the key advantages of the gasification process is its ability to handle a wide variety of feedstocks, from agricultural residues to municipal solid waste. This versatility makes it an attractive option for regions looking to reduce landfill waste while generating renewable energy. Furthermore, the syngas produced can be used in various applications, such as:

- Power Generation: Syngas can be combusted in gas turbines or used in fuel cells to produce electricity.

- Biofuel Production: The gas can be further processed to create liquid fuels like ethanol or biodiesel.

- Chemical Feedstock: Syngas serves as a building block for producing chemicals and fertilizers.

However, it’s important to note that the gasification process is not without its challenges. The initial setup costs can be high, and the technology requires skilled operators to manage the complex systems involved. Additionally, ensuring that the feedstock is clean and free from contaminants is crucial for efficient gasification. Despite these hurdles, advancements in technology continue to improve the viability and efficiency of gasification, making it a promising avenue for sustainable energy production.

Q1: What types of waste can be used in the gasification process?

A1: A wide range of organic materials can be used, including agricultural residues, wood chips, and municipal solid waste.

Q2: Is gasification environmentally friendly?

A2: Yes, gasification is considered more environmentally friendly than traditional waste disposal methods, as it reduces landfill waste and produces renewable energy.

Q3: How does gasification compare to incineration?

A3: Unlike incineration, which burns waste to produce heat, gasification converts waste into syngas, allowing for more efficient energy recovery and less harmful emissions.

Q4: Can syngas be stored and transported?

A4: Yes, syngas can be stored and transported, although it is often converted into liquid fuels for easier handling and distribution.

Environmental Benefits of Biofuels

Biofuels are not just an alternative energy source; they are a beacon of hope for a more sustainable future. As we grapple with the ever-increasing challenges of climate change, the environmental benefits of biofuels become increasingly apparent. One of the most significant advantages is their potential to reduce greenhouse gas emissions. Unlike fossil fuels, which release a substantial amount of carbon dioxide (CO2) and other harmful gases when burned, biofuels can be produced from materials that absorb CO2 during their growth phase. This creates a more balanced carbon cycle, ultimately leading to a decrease in the net emissions of greenhouse gases.

Moreover, biofuels can help divert waste from landfills. When organic waste, such as food scraps and agricultural residues, is converted into biofuel, it not only reduces the volume of waste that would otherwise decompose and release methane—a potent greenhouse gas—but also provides a renewable energy source. This dual benefit highlights biofuels' role in effective waste management strategies, creating a circular economy where waste is transformed into valuable resources.

Another compelling environmental benefit is the conservation of natural resources. Traditional fossil fuel extraction often leads to habitat destruction, oil spills, and water contamination. In contrast, biofuel production can utilize existing agricultural lands and waste materials, minimizing the need for new land conversion. This approach not only preserves biodiversity but also promotes sustainable land use practices. Furthermore, biofuels can be produced locally, reducing the need for long-distance transportation, which contributes to lower emissions and a smaller carbon footprint.

It's also worth noting that biofuels can contribute to improved air quality. When burned, biofuels tend to produce fewer pollutants compared to fossil fuels, including sulfur oxides and particulate matter, which are harmful to human health. This can lead to cleaner air in urban areas, benefiting communities that are often plagued by pollution-related health issues.

To summarize, the environmental benefits of biofuels can be encapsulated as follows:

- Reduction in greenhouse gas emissions

- Waste diversion from landfills

- Conservation of natural resources

- Improved air quality

As we look towards the future, it is clear that embracing biofuels can lead us toward a more sustainable and environmentally friendly energy landscape. By investing in biofuel technologies and infrastructure, we can not only mitigate climate change but also foster a healthier planet for generations to come.

1. What are biofuels made from?

Biofuels are primarily made from organic materials such as plants, agricultural residues, and waste products. Common sources include corn, sugarcane, and vegetable oils.

2. How do biofuels reduce greenhouse gas emissions?

Biofuels reduce greenhouse gas emissions by utilizing materials that absorb CO2 during their growth, thus balancing the carbon cycle when they are burned.

3. Can biofuels help with waste management?

Yes, biofuels can significantly aid in waste management by converting organic waste into energy, thereby reducing landfill volume and associated methane emissions.

4. Are biofuels environmentally friendly?

Biofuels are generally considered more environmentally friendly than fossil fuels, as they produce fewer pollutants and can be sourced from renewable materials.

5. What are the challenges of biofuel production?

Challenges include the cost of production, land use competition, and the need for technological advancements to improve efficiency and scalability.

Economic Impacts of Biofuel Production

The production of biofuels from waste materials is not just an environmental boon; it also has profound economic implications that can reshape local and global economies. As we transition towards more sustainable energy sources, the biofuel industry is emerging as a significant player in job creation, investment opportunities, and energy independence. Imagine a world where waste is not just discarded but transformed into a valuable resource that fuels our vehicles and powers our homes. This transformation not only addresses energy needs but also stimulates economic growth.

One of the most compelling aspects of biofuel production is its potential for job creation. The industry encompasses a wide range of activities, from collection and processing of waste materials to the actual production and distribution of biofuels. According to recent studies, the biofuel sector could generate thousands of jobs, particularly in rural areas where agricultural residues and food waste are abundant. These jobs not only provide employment but also help to revitalize local economies. For instance, a report from the Renewable Energy Association highlights that every job in the biofuel sector can create an additional 1.5 jobs in related industries, amplifying the economic impact.

Furthermore, the investment opportunities in biofuel production are substantial. Investors are increasingly recognizing the potential of renewable energy sources. As governments and private sectors push for cleaner energy solutions, funding for biofuel technologies is on the rise. This influx of capital can lead to the development of advanced technologies that improve efficiency and reduce costs, making biofuels more competitive with fossil fuels. The table below illustrates the projected growth in investment in the biofuel sector over the next decade:

| Year | Projected Investment (in billion USD) |

|---|---|

| 2023 | 10 |

| 2025 | 15 |

| 2030 | 25 |

In addition to job creation and investment, biofuels can also play a crucial role in enhancing energy independence. By converting local waste into fuel, countries can reduce their reliance on imported fossil fuels. This shift not only bolsters national security but also stabilizes energy prices, making economies less vulnerable to global oil market fluctuations. Imagine a country where energy needs are met by local resources, reducing the carbon footprint associated with transportation and fostering a sense of community resilience.

However, it’s essential to acknowledge that the transition to biofuels is not without its challenges. Regulatory hurdles, market competition, and the need for technological advancements pose significant obstacles. Policymakers must create an enabling environment that supports biofuel initiatives through subsidies, research funding, and infrastructure development. By addressing these challenges, we can unlock the full potential of biofuels as a sustainable economic driver.

In conclusion, the economic impacts of biofuel production are multifaceted and promising. From job creation to investment opportunities and energy independence, the benefits are clear. As we continue to innovate and invest in biofuel technologies, we pave the way for a sustainable future that not only addresses our energy needs but also strengthens our economies.

- What are biofuels? Biofuels are renewable energy sources derived from organic materials, such as agricultural residues and food waste.

- How do biofuels impact the economy? Biofuels create jobs, attract investments, and promote energy independence, contributing to overall economic growth.

- What challenges does the biofuel industry face? The industry faces regulatory hurdles, market competition, and the need for technological advancements.

Future of Biofuel from Waste

The future of biofuel from waste is not just a fleeting trend; it’s shaping up to be a cornerstone of sustainable energy solutions. As we face escalating environmental challenges, the need for alternative energy sources has never been more pressing. With advancements in technology and a growing commitment to reducing waste, biofuels derived from organic materials are gaining traction. Imagine a world where the scraps of our daily lives—food waste, agricultural residues, and even municipal solid waste—are transformed into clean energy. This vision is becoming increasingly feasible.

One of the most exciting prospects for the future of biofuels is the integration of innovative technologies. For instance, synthetic biology is paving the way for the development of engineered microorganisms that can efficiently convert waste into biofuels. These tiny powerhouses can be programmed to break down complex organic materials, making the conversion process faster and more efficient. Additionally, the rise of smart waste management systems, equipped with sensors and AI, can optimize the collection and sorting of waste, ensuring that the most suitable materials are directed toward biofuel production.

Moreover, the increasing awareness of environmental issues among consumers and businesses is driving demand for sustainable practices. Companies are now more inclined to invest in waste-to-biofuel initiatives, not only for compliance with regulations but also as part of their corporate social responsibility strategies. This shift in mindset is essential for fostering a circular economy where waste is viewed as a resource rather than a burden.

Furthermore, government policies are evolving to support the biofuel industry. Incentives such as tax breaks, grants, and subsidies for biofuel production can significantly lower the financial barriers for startups and established companies alike. As these policies become more favorable, we can expect a surge in investment, innovation, and job creation in the biofuel sector.

However, challenges remain. The scalability of biofuel production from waste is a critical factor that needs addressing. While many technologies are promising, they must be refined and scaled up to meet the energy demands of a growing population. Collaboration between governments, private sectors, and research institutions will be vital in overcoming these hurdles. By sharing knowledge, resources, and best practices, stakeholders can accelerate the development of efficient biofuel production systems.

In conclusion, the future of biofuel from waste is bright, filled with potential and opportunity. As we continue to innovate and adapt, we can look forward to a world where our waste not only fuels our vehicles but also contributes to a cleaner, more sustainable planet. The journey is just beginning, and with each step, we move closer to a reality where waste is transformed into a valuable energy source.

- What types of waste can be converted into biofuel?

Common sources include agricultural residues, food waste, and municipal solid waste.

- How does biofuel production benefit the environment?

Biofuel production reduces greenhouse gas emissions and helps manage waste effectively.

- What technologies are used in biofuel production?

Technologies like enzymatic hydrolysis and gasification are commonly employed to convert waste into biofuels.

- Will biofuels be a viable energy source in the future?

Yes, with ongoing advancements in technology and increasing environmental awareness, biofuels are expected to play a significant role in our energy future.

Frequently Asked Questions

- What are biofuels and how are they made from waste?

Biofuels are renewable energy sources derived from organic materials, including waste. They are produced through various processes that convert waste materials like agricultural residues and food scraps into usable fuel, helping to reduce greenhouse gas emissions and promote sustainability.

- What types of waste can be converted into biofuel?

Several types of waste can be utilized for biofuel production, including:

- Agricultural residues (like straw and husks)

- Food waste (such as scraps and leftovers)

- Municipal solid waste (general trash and recyclables)

Each of these sources has unique potential for biofuel conversion, contributing to waste reduction and energy production.

- What are the main processing techniques for converting waste to biofuel?

There are several effective processing techniques used to convert waste into biofuel, including:

- Fermentation: This method uses microorganisms to break down organic materials into alcohols that can be used as fuel.

- Anaerobic digestion: This process involves breaking down organic matter in the absence of oxygen, producing biogas that can be harnessed for energy.

- Gasification: This technique converts organic materials into syngas, which can be further refined into biofuels.

- What are the environmental benefits of biofuel production?

Biofuels offer numerous environmental benefits, including:

- Reduction in carbon emissions compared to fossil fuels

- Waste management solutions by repurposing waste materials

- Contributing to energy independence and sustainability

These benefits make biofuels a vital component in the fight against climate change.

- What economic impacts does biofuel production have?

Biofuel production can significantly impact the economy by:

- Creating jobs in the renewable energy sector

- Attracting investment opportunities for businesses

- Promoting energy independence and reducing reliance on imported fuels

These factors contribute to a more robust and sustainable economy.

- What is the future of biofuels from waste?

The future of biofuels from waste looks bright, driven by technological advancements and increasing environmental awareness. Innovations in processing techniques and a growing demand for sustainable energy sources are expected to propel the biofuel industry forward, making it a key player in global energy solutions.